How much does an engineered septic system cost?

How much does an engineered septic system cost?

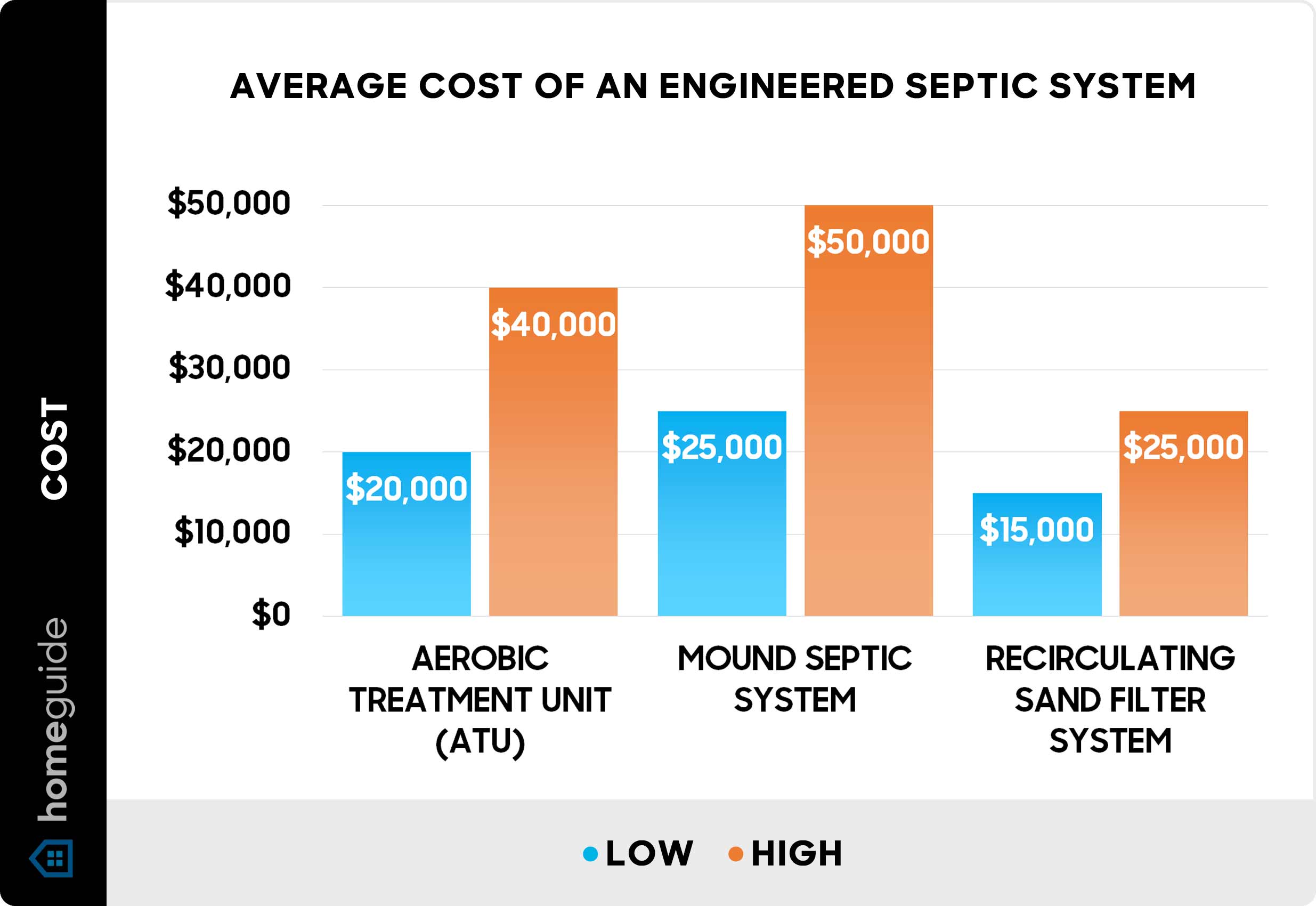

$20,000 – $40,000+ average cost (aerobic system)

$25,000 – $50,000+ average cost (mound system)

Engineered septic system cost

An engineered septic system costs $20,000 to $40,000+ installed for an aerobic treatment unit (ATU) or $25,000 to $50,000+ installed on average for a mound system. The total cost of an engineered septic system varies widely depending on the location, soil and site conditions, system type required, and project complexity.

These advanced wastewater treatment solutions cost significantly more than conventional systems, but they're often necessary for properties with challenging soil, high water tables, or strict local regulations.

| System type | Average installed cost |

|---|---|

| Aerobic treatment unit (ATU) | $20,000 – $40,000+ |

| Mound septic system | $25,000 – $50,000+ |

| Recirculating sand filter system | $15,000 – $25,000+ |

Aerobic treatment unit (ATU)

Aerobic treatment units (ATUs) cost $20,000 and $40,000+ installed on average. ATUs use oxygen to accelerate the breakdown of waste, making them highly efficient for treating wastewater. These systems work well on smaller properties not suited for traditional drain fields.

ATUs require electrical connections to power the aerator pumps, which adds to both installation complexity and ongoing operating costs. They also may require disinfection using chlorine or UV treatment before the wastewater enters the drain field. However, the superior treatment quality often makes ATUs the preferred choice in environmentally sensitive areas.

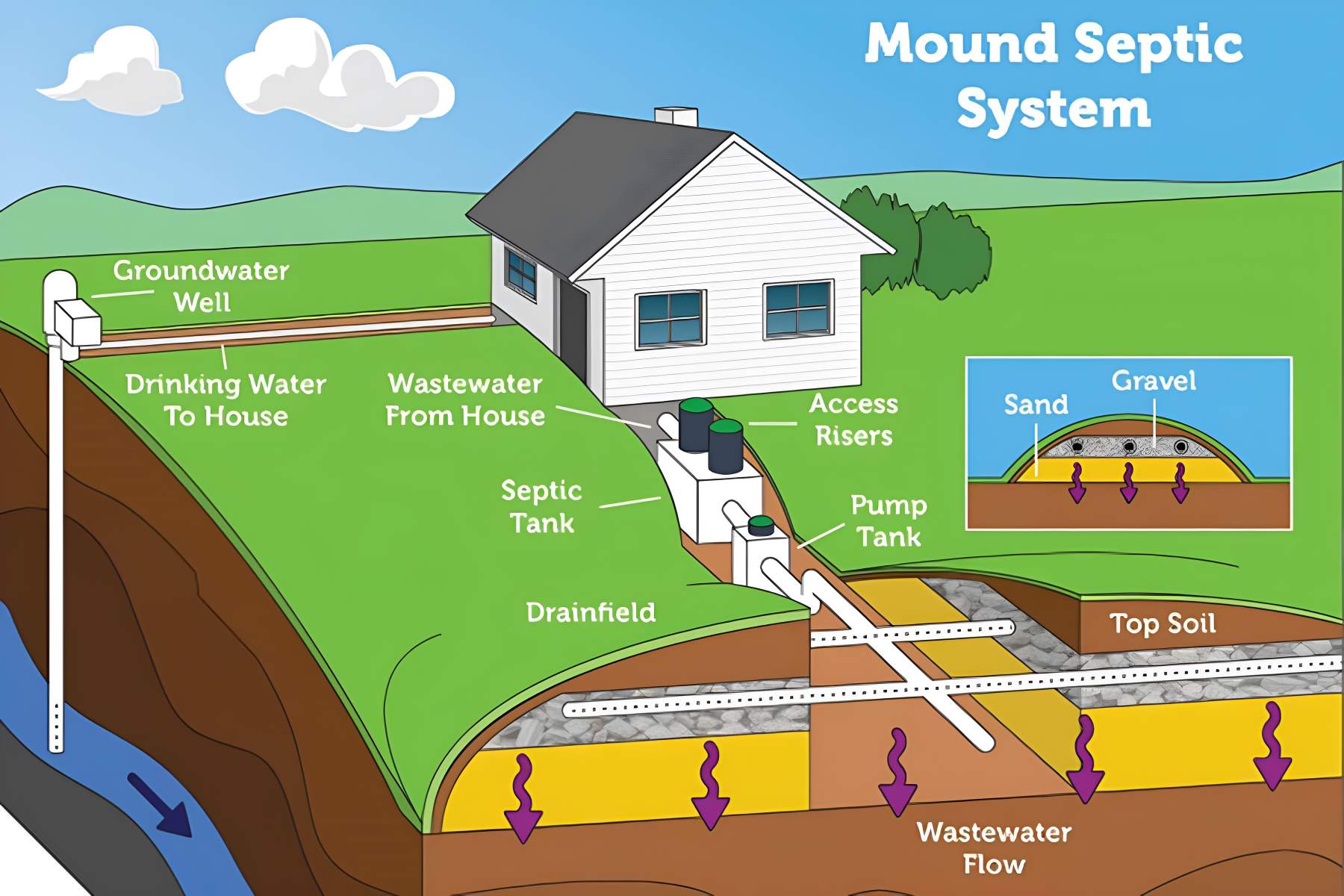

Mound septic system

Mound septic systems cost $25,000 to $50,000+ to install. These systems are the most expensive due to their complexity, but often necessary in areas with high water tables, shallow soil depth, or shallow bedrock. The mound system creates an elevated sand bed above the natural ground level.

Space requirements make mound systems challenging for some properties. A typical residential mound extends approximately 200 feet in length, with additional space needed for larger homes. The construction process involves importing sand and gravel, grading the site, and installing pump equipment.

Recirculating sand filter system

Recirculating sand filter systems cost $15,000 to $25,000+ installed and are suitable for sites with limited space or not enough soil for a traditional system. These systems use layers of sand and gravel in a concrete or PVC-lined box to treat wastewater before it enters the drain field. The wastewater cycles through the sand filter multiple times, with each pass removing more contaminants.

What affects the cost of an engineered septic system?

The complexity of engineered systems means installation requires specialized expertise, advanced materials, and often challenging site preparation work. Each project presents unique requirements that can significantly impact the total investment.

Factors that affect costs include:

Household size: The number of bedrooms or residents in your home determines the size and capacity of the septic system required. Larger households need bigger tanks and more extensive drain fields, which increases costs.

Soil condition: Your site's soil conditions, water table, and local regulations dictate the type of engineered system needed. More complex systems like mound or ATU setups cost more than simpler sand filter systems.

Location: Where you live affects material, labor, and permit costs.

Remote or difficult-to-access properties may require additional site prep or transportation fees.

Urban areas typically command higher labor rates, while rural locations might have limited availability of qualified installers, potentially affecting both the cost and schedule.

Perc testing

A perc test costs anywhere from $200 to $1,500+, depending on the required tests and the soil's location. Percolation testing determines how quickly water absorbs into your soil, which directly influences the type of engineered system you'll need. Local regulations determine a property's perc test requirements.

Failed perc tests often trigger the need for engineered septic systems in the first place. When conventional systems won't work due to soil conditions, engineers use test results to design appropriate alternative solutions for your specific site challenges. Engineering and design fees typically range from $1,000 to $3,000.

Labor

Labor accounts for 50% to 70% of the total septic system cost. Rates vary by region and complexity, ranging from $50 to $200 per hour for specialized installation crews.

Engineered systems require more skilled labor than conventional installations. Technicians must understand complex pump systems, electrical connections, and specialized distribution methods. The installation timeline often extends beyond conventional systems due to additional components and testing requirements.

Site prep

Site preparation represents one of the largest cost variables in engineered septic installations. The more challenging your property, the higher the prep costs.

Preparing your site for installation may include the following:

Excavation costs $2.50 to $15.00 per cubic yard and is required to install tanks and drain fields. Rocky, sloped, or wet sites can drive up the cost significantly.

Tree removal costs $300 to $2,000 per tree, depending on the size.

The cost to level or regrade the yard may add $500 to $5,000 to ensure proper drainage and system function.

Permits and inspections

Expect to spend $500 to $2,000 on the permits and inspections needed to ensure your system meets local and state regulations. Engineered systems often require additional permits beyond standard septic installations. Environmental impact assessments, electrical permits for pumps, and specialized disposal permits may apply depending on your system type and local regulations.

Materials

Engineered septic systems use specialized components that cost more than conventional septic materials. Pump systems, electrical controls, and treatment media represent significant material expenses.

Sand filter systems require specific sand gradations that meet engineering specifications. Using incorrect materials can compromise the system's effectiveness, so sourcing from qualified suppliers is essential, even when costs are higher.

Maintenance

Proper maintenance keeps your engineered septic system running smoothly and helps avoid costly repairs down the road. Routine maintenance includes inspections, pumping, and occasional repairs. Plan for the following ongoing costs:

| Service | Average cost | Details |

|---|---|---|

| Septic tank inspection cost | $150 – $450 | Inspections as part of routine maintenance determine the condition of the tank and pipes and when the tank needs pumping. |

| Septic pumping costs | $300 – $700 | Prices depend on the tank size and condition, with larger and older tanks taking longer and costing more. |

| Septic filter cleaning | $100 – $400 | This service improves the efficiency of the septic system and may be included with pumping service. |

| Septic tank additives (Pro) | $400 – $600 | Additives are rarely needed in a well-maintained septic system but are added by a professional to an unhealthy tank to re-establish a healthy bacterial balance. |

| Septic tank additives (DIY) | $50 – $200 | While readily available, these products are best used by professionals since the additives can corrode the tank, harm the bacterial balance, and contaminate groundwater. |

Engineered septic system FAQs

What is an engineered septic system?

An engineered septic system is a custom-designed wastewater treatment solution for properties where standard systems won't work. These systems use advanced technology and specialized components to safely treat and disperse household wastewater, even in challenging soil or site conditions.

When do you need an engineered septic system?

If your property can't support a conventional septic system, an engineered septic system may be your best or only option. You'll need an engineered system if your property has:

High water table

Poor or shallow soil

Steep slopes

Small lot size

Local regulations that prohibit standard systems

A soil test and site evaluation by a professional will determine if your property requires an engineered solution.

How long does it take to install an engineered septic system?

Installing an engineered septic system takes 1 to 3 weeks on average, depending on site complexity, permitting, weather, and system type. However, more complicated sites or extensive engineering requirements can extend the timeline by several weeks or months.

How long does an engineered septic system last?

With proper maintenance, an engineered septic system can last 15 to 40+ years. Many variables, such as home size, system type, material durability, soil conditions, and water usage, dictate how long your system will last. Keeping up with maintenance and avoiding harmful chemicals can significantly extend the system's life expectancy.

Getting estimates from septic system engineers

The complexity of engineered septic systems means estimates can vary significantly based on assumptions about site conditions and system specifications. Follow these guidelines to get accurate estimates from qualified potential contractors:

Request itemized quotes that break down labor, materials, permits, and engineering fees.

Ask about site-specific challenges that could impact costs.

Verify the engineer's experience with your required system type.

Ensure the engineer is licensed and familiar with local regulations.

Compare at least three estimates with similar details before making a decision.

Questions to ask the septic system installer

Before hiring a septic installer, ask these important questions to ensure you're getting quality work and a fair price:

Are you licensed, bonded, and insured for septic installation?

How many engineered septic systems have you installed in this area?

Can you provide references from recent customers?

What type of system do you recommend for my property, and why?

What is included in your estimate?

How do you handle unexpected site issues or changes during installation?

What is your warranty on labor and materials?

What maintenance services do you offer after installation?